A very interesting article, Hydraulic Fracturing and Laboratories: What Does it Mean for You? by The Association of Public Health discusses how fracking has been in use for decades, but the science used to test and research the effects it has on our environment is just in the beginning stages. The EPA is conducting research on fracking and its potential impact on groundwater, but the full report is not set to be released until 2014. With an industry growing as quickly has the fracking industry, two years of high-volume operation before we gain a better understanding of potential pitfalls is a large gamble to take.

So far, fracking has been blamed for contaminated drinking water and dangerous emissions (such as methane gas leaked from drilling equipment) in states such as PA, WY, TX, CO, NM, and OH. No comprehensive investigation by state or federal government has been done on how fracking affects human health, but the instances of people (and animals) becoming seriously ill near fracking sites continues to rise. ProPublica also published a more in-depth article, Science Lags as Health Problems Emerge Near Gas Fields, earlier this year. While a bit longer of a read, it is a great resource for information. Beware, it may leave you with more questions than answers!

What is your opinion on fracking and its environmental effects? Do you think with more regulation meant to control contamination and pollution that hydraulic fracturing can be safely used?

Let's start a discussion! Leave your comments below!

If you need more information on what fracking is, read our blog post. There is also a blog post regarding what chemicals are used in fracking fluid.

For over 40 years, Oil Skimmers, Inc. has been the leader in the field of waste oil removal. We are the leading manufacturer of automatic oil skimming equipment, specializing in recovering all types of floating waste oils, greases and fats from the surface of water and other liquids. Over the years, we have solved more than 25,000 applications. This has given us the skills and knowledge necessary to tackle even the most challenging problem, and we want to share our knowledge with you.

Thursday, April 26, 2012

Tuesday, April 24, 2012

AIST 2012: Come See the Model 6V Oil Skimmer in Action!

Oil Skimmers, Inc. Will Exhibit at AIST

2012

The annual Association for Iron and Steel

Technology (AIST) trade show will take place on May 7-10 2012 at the Georgia World Congress

Center in Atlanta, Georgia. AIST focuses on new technologies on the global

stage aimed at helping those in the iron and steel industries improve

productivity and efficiency. Featuring hundreds of technical presentations plus

hundreds of exhibitors and attendees, AIST is a great opportunity to expand

your knowledge base about cutting-edge innovations and to network with people in

all facets of the iron and steel industries.

Regional

Sales Managers Rob Fiorilli and Ken Gray will be at the Oil Skimmers, Inc.

booth during AIST answering any questions regarding Oil Skimmers’ products and

how they can be useful in the iron and steel industries. They can also provide

details about exactly how these tube Oil Skimmers have helped many companies in these

industries. During the show, a Model 6V Oil Skimmer will be in operation for

visitors to view and examine. There will also be a power point presentation running that provides information and pictures about our Oil Recovery & Transfer System (ORTS, formerly known as OHDT). Please stop by, take a look and say hello! Booth

# 1065!

You can request more information about our Oil Skimmers here.

Is anyone else attending the AIST show in Georgia this year? What are you most looking forward to at the show? What industry are you representing? Leave us a comment and let us know!

Is anyone else attending the AIST show in Georgia this year? What are you most looking forward to at the show? What industry are you representing? Leave us a comment and let us know!

Monday, April 16, 2012

What Chemical Additives are Used in Fracturing Fluids and Why

Senthil Kumar had a great question for us regarding our post about Hydraulic Fracturing!

Senthil Kumar 5 hours ago

can anybody say why a small amount of additives is mixed in fracture fluids.

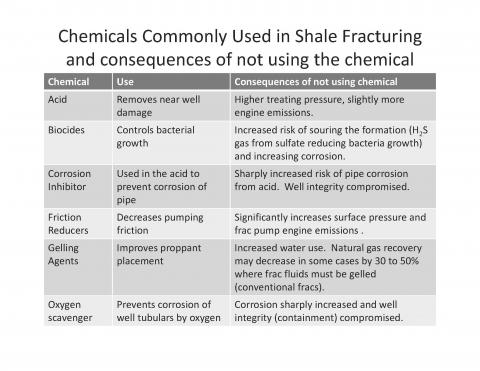

While the specific chemicals used varies by company and is often dictated by the condition of the well being drilled, there are general types of chemicals used. Below is a chart (original can be found on FracFocus) that explains several types of chemicals, the reason for usage, and what the consequences could be if they are not used.

An additional source of information regarding hydraulic fracturing and the chemicals used in fracking fluids can be found at geology.com. The specific page regarding fracking fluids is here. This site lists several more chemicals that may be used as additives, in addition to the 6 listed above.

FracFocus also provides a "find a well" service; visitors enter their state and county, and the site lists hydraulic fracturing wells in that county (if there are any). Visitors can go down the list of counties to locate wells that are in neighboring areas. Once a visitor finds well locations, they can pick a particular well and view a PDF file of what chemicals were added to the fracking fluids for that particular well.

How safe do you think the chemical additives in fracking fluids are? Since not all of the fluid can be removed from the wells (see our original hydraulic fracturing post for that information), do you think there is a potential for drinking water to be contaminated? Please leave a comment with any thoughts or questions! This is certainly an important topic in our world today.

Thursday, April 12, 2012

Want Instant Updates and Pictures?

We've joined Twitter! We'll be sending out updates and pictures from upcoming trade shows (such as AIST 2012 in May!), plus any interesting applications our representatives encounter, or news and contest updates.

Follow us and see what it's all about!

https://twitter.com/#!/OilSkimmersInc

Follow us and see what it's all about!

https://twitter.com/#!/OilSkimmersInc

Monday, April 2, 2012

Hydraulic Fracturing: What it is, How it's Regulated, and How Oil Skimmers are Helping with Clean Up.

Hydraulic

fracturing (fracking) is a process that recovers natural gas and oil from

deep shale formations that contain large amounts of the fuels. Fracking

requires the drilling of a well vertically underground, past the deepest

aquifer containing fresh groundwater, anywhere from hundreds to thousands of feet below the ground's surface. Steel surface casing is inserted down the

well and cement is pumped in to create a barrier between the well bore and

groundwater. The vertical drilling is often paired with horizontal drilling, ranging from 1,000-6,000 feet away from the vertical well. Fracturing fluids – a mix of water and sand plus several additives – is then injected at high pressure into the formation to create

fissures (a narrow opening or crack).

When the pumping of the fluids is

stopped, the internal pressure of the geologic formation causes most of the injected fluids to rise to the

surface; this fluid is called flowback.

The sand remains in the fissures and keeps them open, allowing gas and oil to flow. The flowback can be disposed of either by surface discharge where authorized under the Clean Water Act (read more about this act here) or by injection into Class II wells as authorized under the Safe Drinking Water Act (see the EPA page here), or it can be recycled in a closed system for future use. The National Pollutant Discharge Elimination System (NPDES) regulates discharge

of flowback and requires it to be treated prior to allowing discharge (read our blog post about the NPDES to learn more). This is

where Oil Skimmers, Inc., steps in.

Oil Skimmers, Inc. has helped two companies with the use of a Model 5H Oil Skimmer. This Oil Skimmer

removes oils and greases from the surface of the flowback. One company wanted to remove oils and greases in order for the flowback to be re-used by a drilling company, while the other needed to meet discharge regulations. Customers have found

that by removing the free oils and greases prior to other treatment, the

process is more efficient, less costly, and requires less maintenance.

The EPA is conducting a study of fracking and the potential impact it may have on our drinking water and groundwater, with initial reports to be released sometime during the end of this year and a full report being released in 2014. Read more about the study at the EPA site, on this page.

Learn more about our Oil Skimmers at www.oilskim.com!

Subscribe to:

Posts (Atom)